Maintenance of vacuum circuit breaker

Vacuum circuit breakers are now widely used in industrial production and distribution, very common products such as VS1-12 vacuum circuit breakers, but because of its high working voltage rating, high current, flying fox capacity, resulting in many problems and hidden dangers, a single improper handling, may lead to many accidents. Therefore, this requires us to strengthen the management of vacuum circuit breaker selection, installation, operation, maintenance and repair process, the operating vacuum circuit breaker state monitoring and diagnosis, the common faults can be dealt with in a timely and accurate manner.

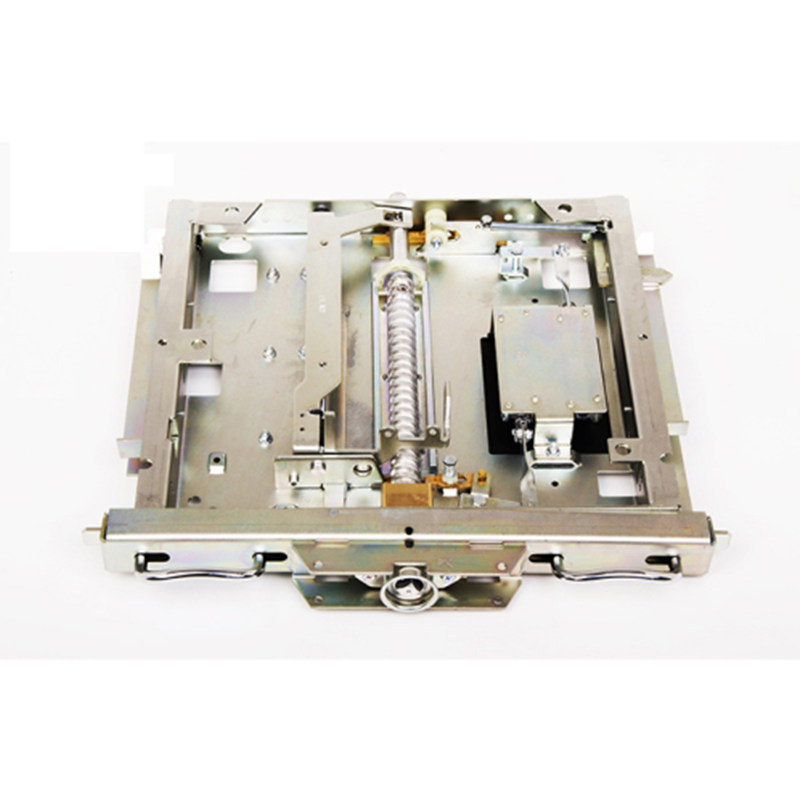

1, commissioning and handover test strictly put the equipment commissioning and handover test, in order to prevent changes in transport and institutional adjustment of the equipment mismatch, especially the operating mechanism and the vacuum circuit breaker after the connection of the problem.

The main re-test parameters are: closing bounce, breaking the same period, open distance, compression stroke, closing and breaking speed and time, DC resistance, breaking and closing action voltage value, break insulation level, transmission acceptance test, etc. These parameters should meet the requirements. In our usual routine maintenance work, we mainly found the following problems: the static contacts in the circuit breaker cabinet are difficult to enter the car due to the expansion gear plate and the frame of the trolley type circuit breaker, the bounce and travel of the circuit breaker are not qualified, the insulator of the circuit breaker body is broken because the distance between the insulator and the tie rod is too close, the closing contactor action characteristics are not good, often after one action cannot be acted or the action voltage gradually increases, the vacuum bubble is not in line with the requirements. vacuum bubble does not meet the requirements, etc., we have dealt with these problems. On the vacuum circuit breaker commissioning and handover test work must be done strictly. We have to find the insulation breakdown, abnormal mechanism, vacuum interrupter leakage, as well as bounce, speed, stroke abnormalities and other unqualified conditions, and deal with them before commissioning to ensure operational safety.

2, operation and maintenance, regular inspection

2.1, operation and maintenance of the operating operation to observe whether there are abnormal phenomena, such as in the circuit breaker after disconnection, whether there is an abnormal discharge sound, power supply, observe the vacuum interrupter chamber has no cracks, broken. Abnormalities found immediately reported, to be overhauled to confirm, then operate.

2.2, regular inspection of the vacuum circuit breaker body common defects are: vacuum interrupter leakage, the body insulation parts breakdown, over-voltage protector failed, vacuum interrupter DC resistance failed, the new input circuit breaker refuses to close and refuse to divide and so on. Periodic voltage test, vacuum measurement, DC resistance and breaking operation voltage value is an important means to find the above defects.

3, vacuum circuit breaker condition monitoring and diagnosis

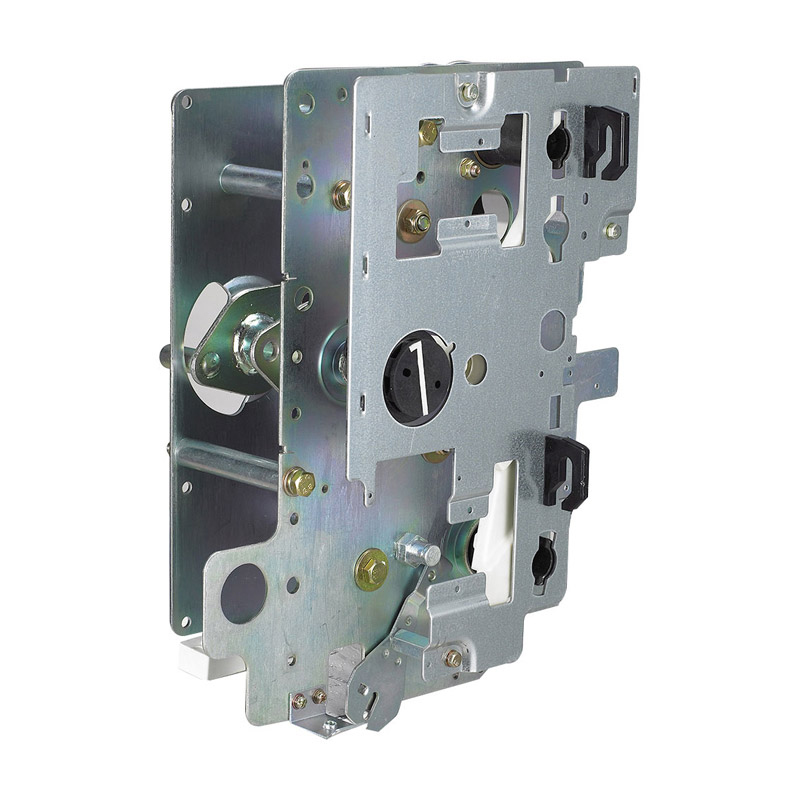

The vacuum interrupter is the key component of vacuum circuit breaker, which is supported and sealed by glass or ceramic, with dynamic and static contacts and shield, and the vacuum level cannot be lower than 6.6 x 10-2P a. The new vacuum interrupter manufactured by the factory is required to reach below 7.5 x 10-4Pa. When the vacuum level decreases, the opening performance is significantly reduced. Therefore, the vacuum interrupter cannot be hit by any external force or suffer from collision.

3.1 The most important feature of vacuum interrupter is that the contacts are enclosed in the insulating shell of the vacuum interrupter, which is manufactured with modern equipment under strict quality control to ensure long life. In the following cases need to be inspected, if necessary

The vacuum bubble needs to be replaced if

(I) when the vacuum interrupter has reached the guaranteed number of interruptions by the manufacturer (mechanical life I million times).

(2) The vacuum interrupter has reached the specified inspection cycle (when the number of divisions and closures reaches I million times and the short-circuit current reaches 100 times, the interrupter's voltage test is conducted and the vacuum interrupter is replaced when it reaches 20,000 times).

(3) When abnormalities are found in the appearance. Inspection basis: The life of vacuum circuit breaker is judged by 2 indicators of contact and vacuum degree.

(1) Measurement of contact wear. Use the vacuum circuit breaker contacts on the rod engraved on the mark to check or use vernier calipers to determine the contact overtravel. If the accumulated wear thickness of dynamic and static contacts exceeds the specified range, it indicates that the electrical life of the vacuum bubble has ended, the vacuum bubble should be replaced.

(2) The DC resistance of the vacuum bubble is within the specified range. General vacuum bubble DC resistance is not more than 2 5μΩ, vacuum circuit breaker conductive circuit resistance is not more than 45μΩ

(3) vacuum degree measurement.

① Frequency withstand voltage method. Make the circuit breaker in the disconnected state, add voltage between the contacts of the vacuum interrupter chamber to determine, can withstand 42kV, Imin frequency withstand voltage test, the vacuum bubble should not have a continuous discharge, then considered normal.

② Vacuum tester test. At present, the more accurate method is the magnetic control method, suitable for the manufacturer as a vacuum interrupter detection. The vacuum degree is not more than 5*10-4Pa.

③ Spark meter method. Only for the glass tube vacuum interrupter, when using, let the spark detector in the interrupter surface movement, in its high-frequency electric field under the action of different internal luminescence. If there is a light green glow inside the tube, then the vacuum degree is above 1.33 * 10-5; if the red and blue light, that the tube has failed; if the tube has been in the atmosphere, it will not glow.

.jpg)