Notes on vacuum circuit breakers

When testing, you should gradually move closer to the energized equipment to glow or sound stop to verify the integrity of the vacuum circuit breaker. Then test the equipment in the need for power testing. The same pole erected multi-layer line test, should be tested first low-voltage, then high-voltage test, first test the lower layer, then test the upper layer. Need special instructions, in storage and transport, do not make it strong vibration or impact, not allowed to adjust the disassembly, where there is rain and snow and other environments that affect the insulation performance, must not be used. Mutual transformer calibrator is simple, readings are intuitive, rapid measurement, can reduce power consumption, reduce labor intensity; small size, light weight, easy to carry and field testing; mutual transformer calibrator can be tested at 5% of the fixed working current. Vacuum circuit breaker is a good protection equipment, can play an important role and value in the use, mainly used to test equipment to ground voltage in more than 250V high-voltage electrical equipment.

Vacuum circuit breaker in use has different forms and types, before using the vacuum circuit breaker test, be sure to carefully read the instruction manual, check whether the test is over cycle, whether the appearance of damage, broken. For example, GDY type vacuum circuit breaker when removed from the package, first of all, should observe whether the electric rotation indicator blade is off-axis phenomenon, whether the alarm sound, off-axis shall not be used, then the electric rotation indicator in the hands gently shake, its blade should be slightly swing, prove good, and then check the alarm part, prove good sound. For GSY type series high-voltage sound and light type vacuum circuit breaker should be self-testing test of the indicator before operation before the indicator is rotated and fixed on the operating rod and the rod is stretched to the specified length, and then only after a self-test.

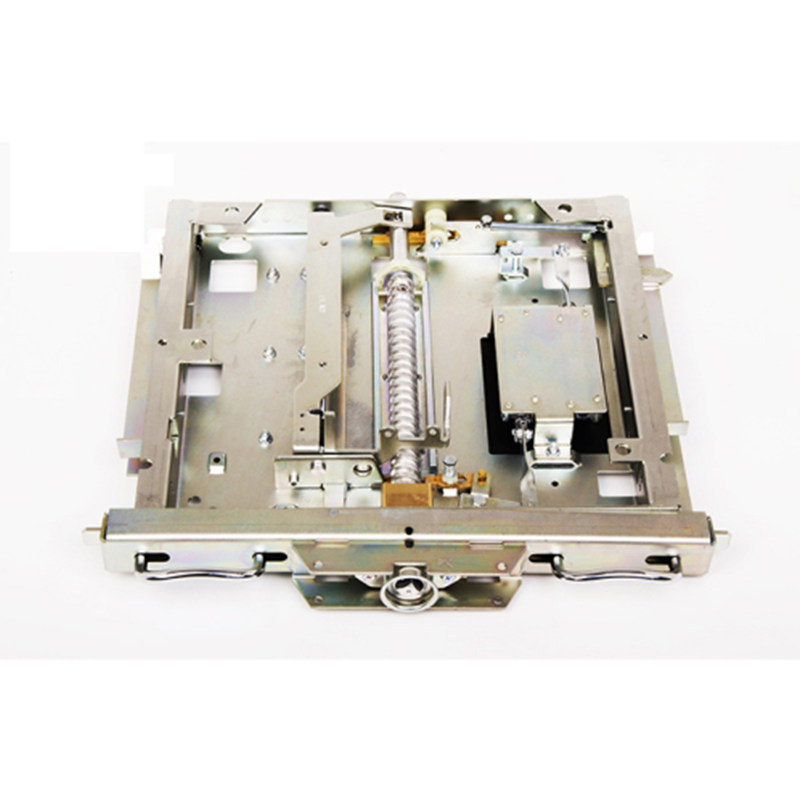

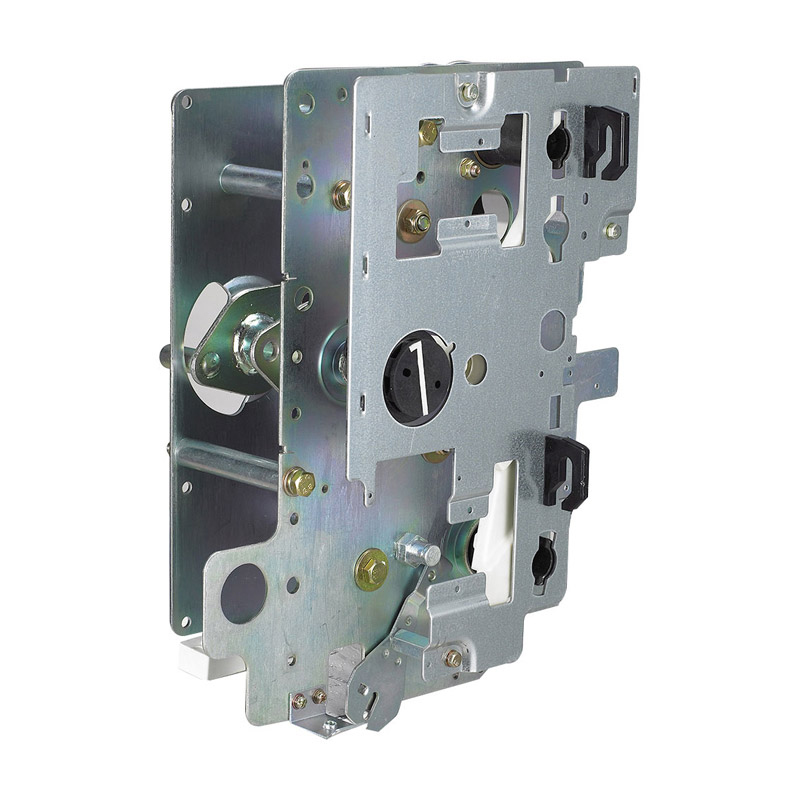

Note that the vacuum circuit breaker cannot detect the DC voltage. When testing, the operator must wear insulated gloves and insulated boots to prevent injury to the human body from stride voltage or contact voltage. The operator should hold the grip part below the hood guard ring in hand and test on powered equipment first. At present, there are three types of widely used: luminous type high vacuum circuit breaker, sound and light type vacuum circuit breaker and windmill type vacuum circuit breaker. They are generally composed of three major parts: the detection part (indicator part or windmill), the insulation part and the grip part.

The vacuum circuit breaker should be reasonably inspected before use to ensure that it can play an important role and value in use. In the use of vacuum circuit breakers for power testing, first of all, you must carefully implement the operation guardian system, one person to operate, one person to supervise. The operator in the front, the guardian in the back. When using the vacuum breaker, you must pay attention to its fixed voltage to be compatible with the voltage level of the electrical equipment under test, otherwise it may endanger the personal safety of the operator or cause wrong judgment. Do not put it in the open air under the hot sun, it should be kept in a dry and ventilated place, and do not wipe or touch it with corrosive chemical solvents and detergents.

The insulated part refers to the part from the lower metal articulation screw of the indicator to the end of the cover ring, and the grip part refers to the part below the cover ring. The insulation part and the grip part are different in length according to the voltage level. The vacuum circuit breaker is produced and used in accordance with the normal way and method to ensure that it can be produced and used in accordance with certain principles and methods.

.jpg)