Types of high voltage grounding switch and considerations

The high voltage earthing switch is usually part of the disconnecting switch and is a mechanical earthing device that does not pass load current under normal circumstances and can withstand a certain amount of time when a fault such as a circuit break occurs in order to ensure the personal safety of maintenance personnel. High-voltage grounding switch is commonly used in high-voltage switchgear, as a safety protection device, although in normal times it will be considered to be of little use, but in the event of a circuit fault requiring maintenance, it is a device that must be used to ensure the safety of the circuit and personnel. The following is a brief introduction to the type of high-voltage grounding switch, high-voltage grounding switch use precautions it

High voltage grounding switch types

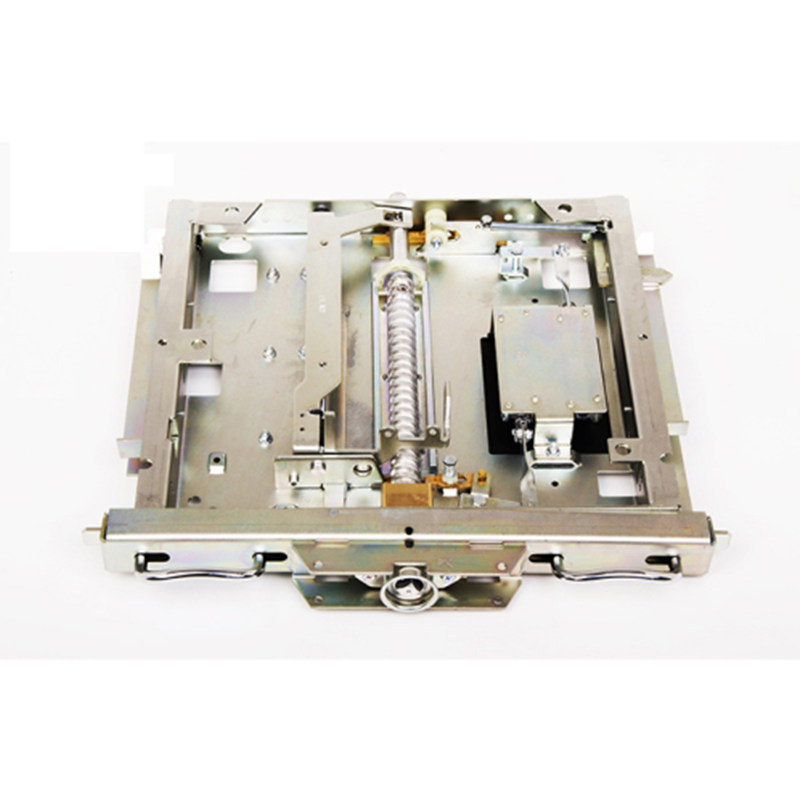

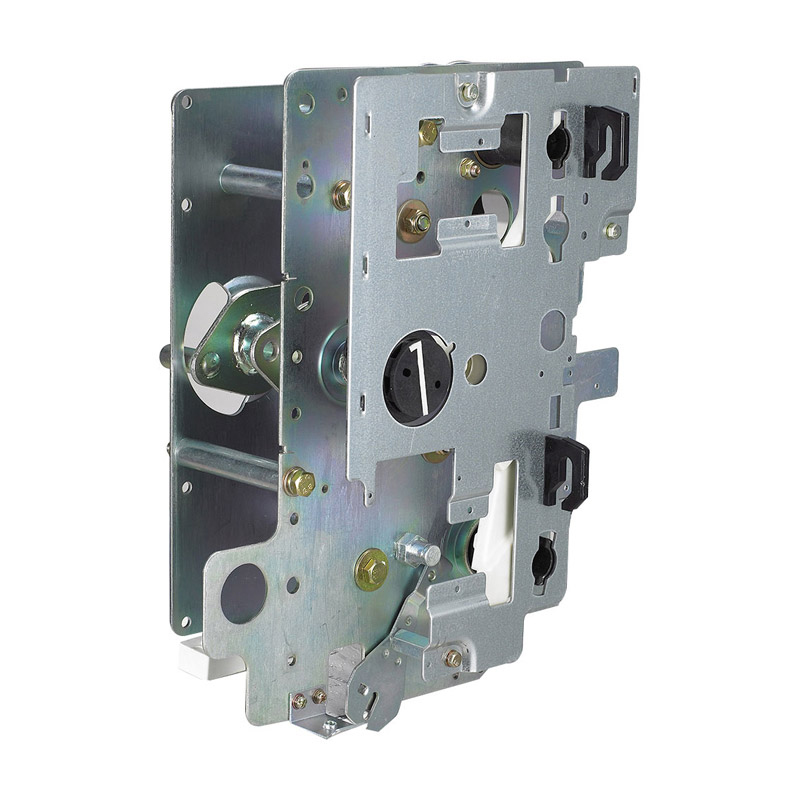

According to the different requirements of the installation location, high-voltage grounding switch is divided into two types of high-voltage grounding switch for maintenance and fault fast shutdown high voltage grounding switch. The grounding switch is used for equipment maintenance to form an obvious grounding point on each side of the equipment that may call, mainly busbar grounding switch, emergence, into the line of high voltage grounding switch, etc. Fault fast shutdown grounding switch has the ability to shutdown short-circuit current as well as open and close induction current, operated by electric spring mechanism, fault grounding switch is suitable for line out side grounding switch, as a protective device when overhauling, with the relevant disconnecting switch, circuit breaker has electrical chain.

Notes on the use of high-voltage grounding switches

1, the use of the process should keep the appearance of high-voltage grounding switch clean and intact, the surface of the porcelain sleeve without cracks and scars, insulating metal and porcelain parts of the glue installed with good performance of waterproof sealant, paint integrity, the correct logo.

2, when using should check whether the secondary wiring connection in the operating mechanism box is tight, whether the transmission device, secondary small switch and blocking device are firmly installed, whether the heater model meets the standard and can be used normally.

3, Check the bracket and grounding lead to ensure that it is free of rust and damage, grounding is good, the fixed bolt of the grounding lead should be fitted with an elastic gasket, check whether the grounding lead is clearly marked.

4, Check whether the wiring situation and electrical connection are reliable, whether the bolts meet the torque, each contact surface should be coated with power compound grease, the loose and tight setting of the lead is appropriate, no obvious over-tightening and over-loose phenomenon.

.jpg)