How is the insulation performance of solid insulated switchgear achieved?

The insulation properties of Solid Insulated Switchgear are achieved through a combination of technical means and design principles. These are designed to ensure safe and reliable operation at high voltages and in harsh environments. The following are some of the key aspects.

1. Selection of insulating materials

Solid insulated switchgear mainly uses epoxy resin as the main insulating medium. Epoxy resin is an important type of thermosetting resin. Its molecular structure contains two or more epoxy groups and can form a three-dimensional network solid in the presence of appropriate chemical reagents. The cured epoxy resin has excellent insulation properties, low water absorption, no longer has active groups and free ions, and can effectively prevent current leakage and insulation breakdown.

2. Unique structural design of solid insulation

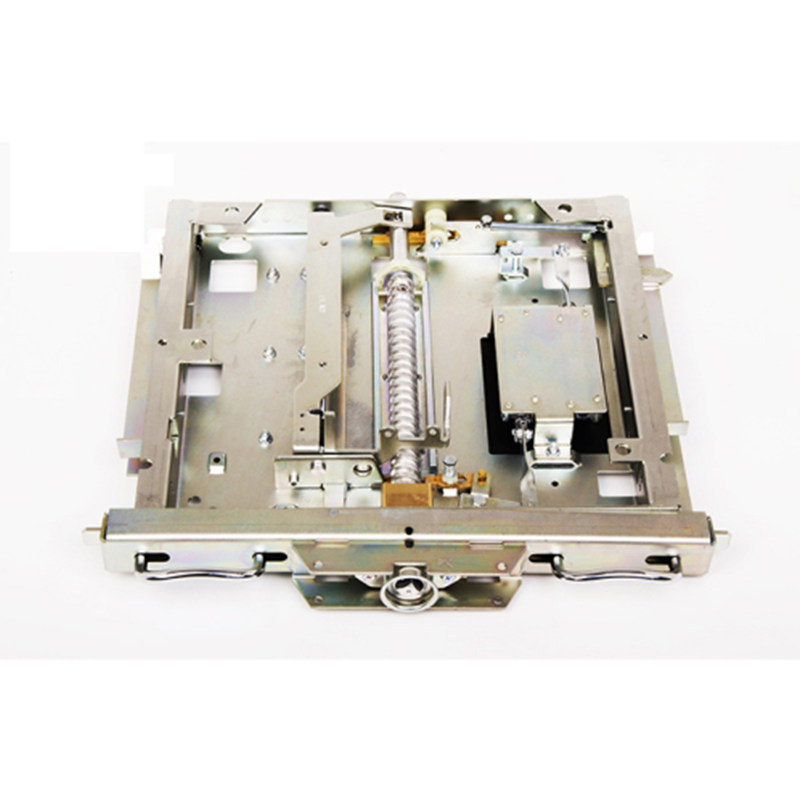

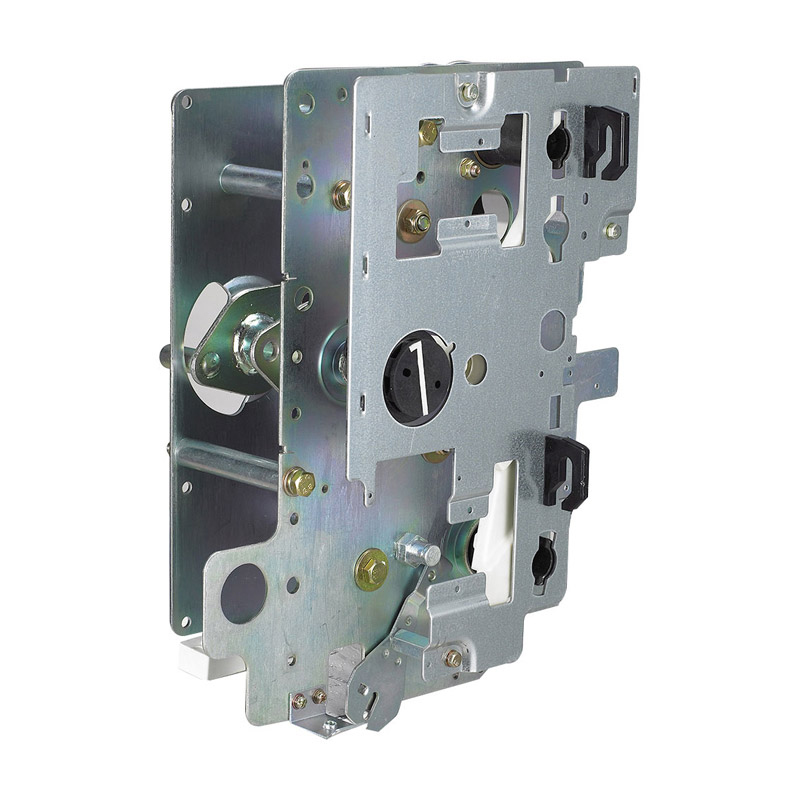

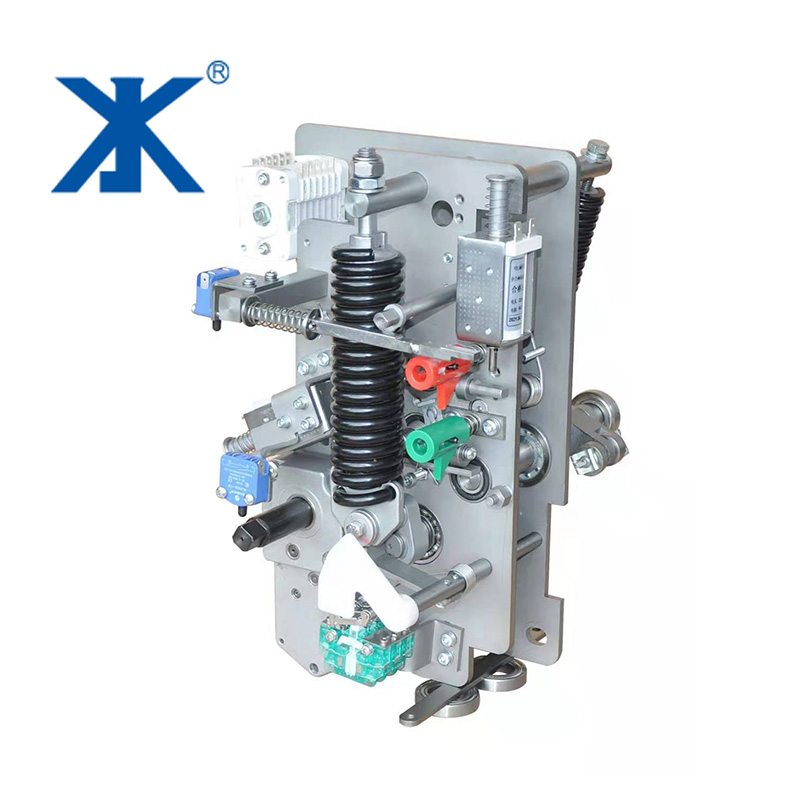

(a) Through the APG automatic gel process, the main conductive circuit components such as circuit breakers, disconnectors, and conductive connections are completely sealed in epoxy resin. This integral casting method reduces the connection points between components, thereby reducing the failure rate and improving insulation performance.

(b) Solid insulated switchgear usually adopts a fully enclosed structure, which completely isolates the inside of the equipment from the external environment. This design can effectively prevent impurities such as moisture and dust in the external environment from entering the inside of the equipment, causing adverse effects on insulation performance.

3. Surface treatment technology

conductive or semi-conductive shielding layer is usually coated on the surface of the solid insulated switchgear. This shielding layer can not only protect the insulating material from the influence of the external environment, but also improve the overall electrical performance of the equipment and reduce the risk of partial discharge.

4. Manufacturing process

During the manufacturing process, it is necessary to strictly control the process parameters of each process to ensure the curing degree and quality of the epoxy resin. At the same time, the finished product needs to be strictly tested, including insulation resistance test, withstand voltage test and partial discharge test, to ensure that the insulation performance of the equipment meets the design requirements.

5. Other measures

(a) Although solid insulated switchgear basically does not require maintenance during normal operation, in order to ensure the long-term stable operation of the equipment, regular cleaning, inspection and maintenance are still required.

(b) In order to ensure the durability and reliability of the enhanced insulation, a sufficient safety distance must be maintained in the equipment to prevent insulation breakdown accidents under high voltage conditions.

In summary, the insulation performance of solid insulated switchgear mainly depends on the selection of insulating materials, structural design, surface treatment technology, manufacturing process and other related measures. These measures work together to ensure that the solid insulated switchgear has excellent insulation performance and stable and reliable operation performance.

.jpg)