What does solid insulated switchgear consist of?

Solid insulated switchgear is a special type of switchgear that uses solid materials (such as epoxy resin) as insulators and completely encapsulates live parts inside the insulating material through a specific process to achieve electrical isolation and insulation protection. So what are its components?

1. Functional unit

It is mainly composed of three units, namely circuit breaker unit, load switch unit, and combination electrical unit.

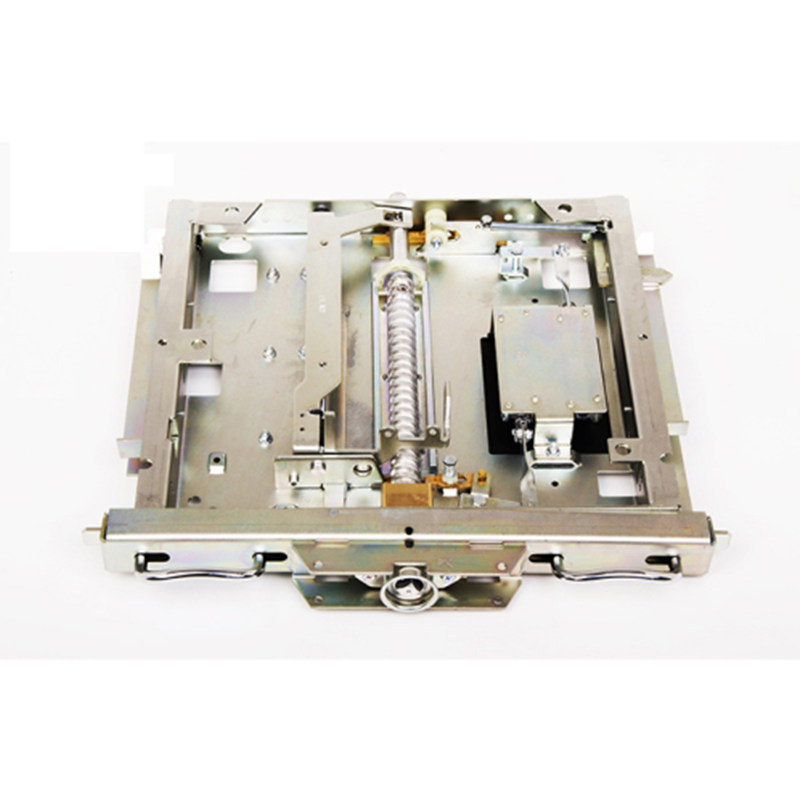

(a) Circuit breaker unit: responsible for the opening and closing of the circuit, it is the core component of the switchgear and has short-circuit protection and overload protection functions. Such as our company's Solid insulated ring network cabinet core unit

(b) Load switch unit: mainly used to control the on and off of the load, and can open and close the circuit under normal load current, but is generally not used for fault current interruption.

(c) Combination electrical unit (or F unit): integrates a variety of electrical components and functions, such as disconnectors, grounding switches, etc., to achieve more complex circuit control and protection.

These functional units can be configured according to system requirements, and can be used alone or expanded and combined to meet different application scenarios.

2. Structural composition

Each functional unit is usually divided into the following parts in structure:

(a) Instrument room: used to install intelligent controllers (such as microcomputer protection devices) and other meters to monitor and control the circuit.

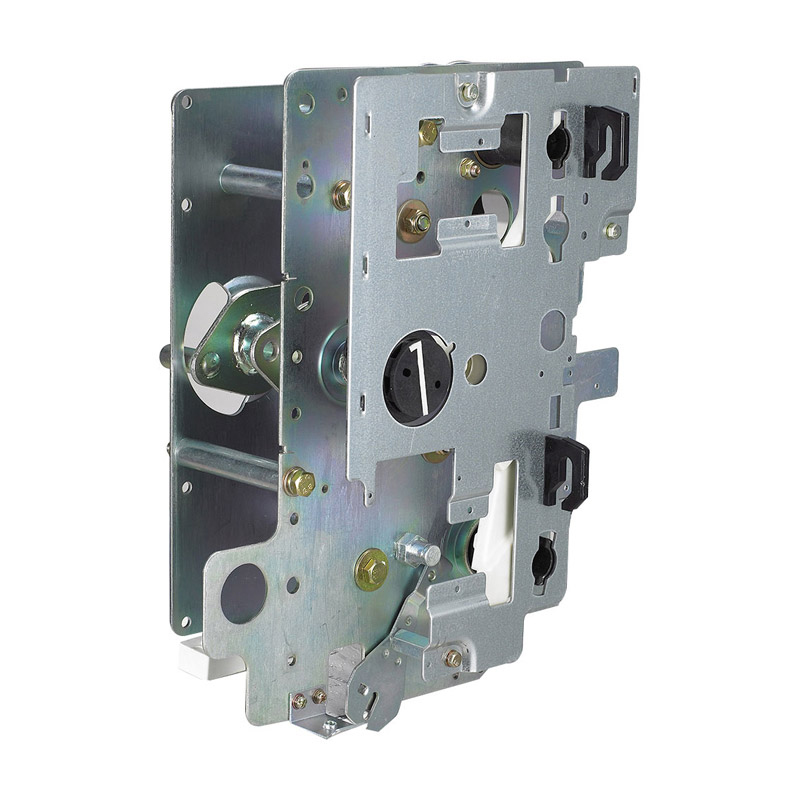

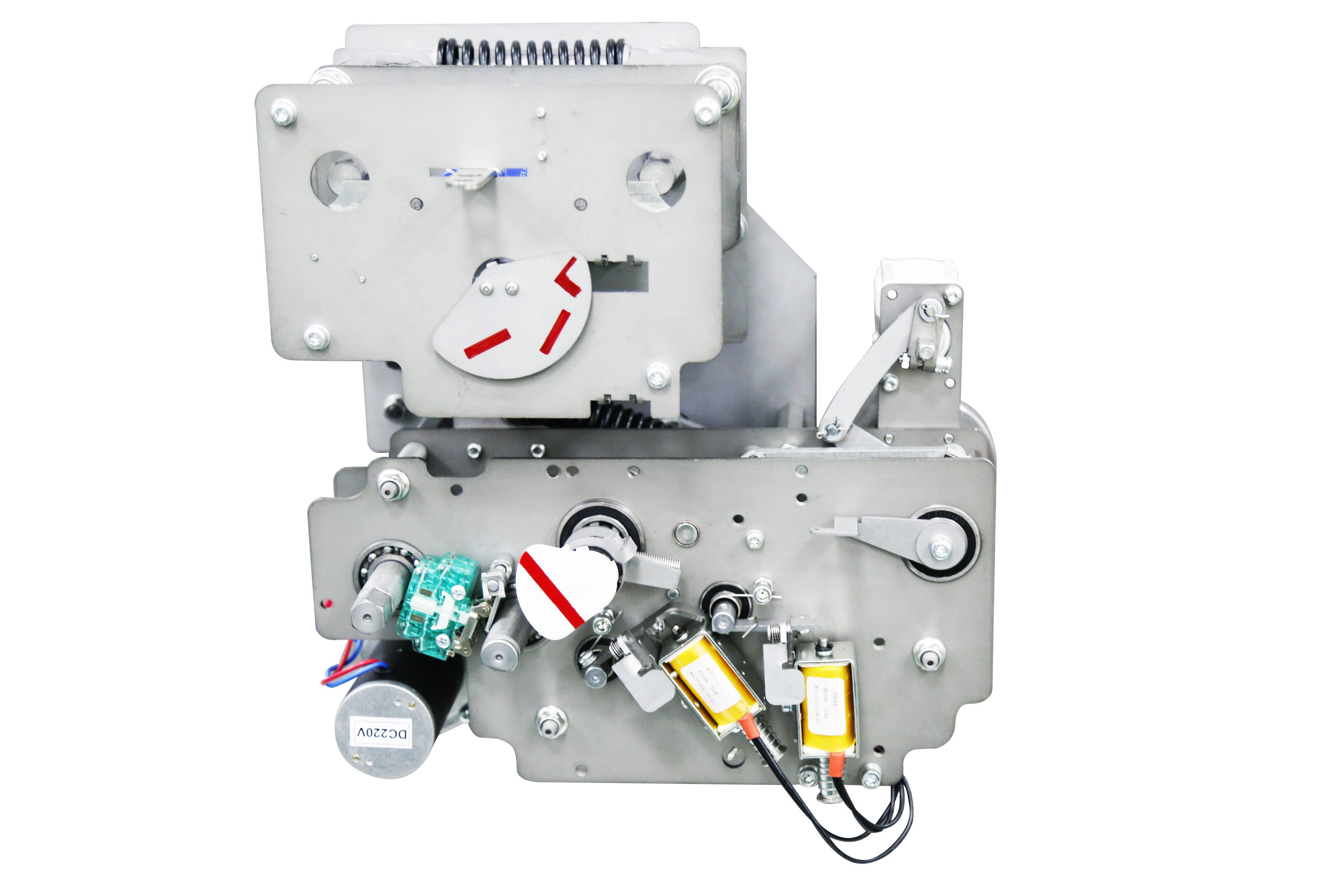

(b) Operating mechanism: including manual and electric operating mechanisms, used to operate circuit breakers, load switches and other equipment. Special spring operating mechanism is a common choice, which has high reliability and stability.

(c) Primary circuit: It is the core part of solid insulated switchgear. The busbar, disconnector and arc extinguishing chamber are completely sealed in epoxy resin using APG automatic gel process. This process ensures high insulation performance and long life of the equipment while reducing maintenance workload.

3. Technical features

1. Since the primary circuit is completely sealed with epoxy resin, the solid insulated switchgear has excellent insulation performance and can effectively prevent accidents such as electric shock and short circuit.

2. Using high-quality materials and advanced manufacturing processes, the solid insulated switchgear has a long service life and stable performance.

3. Due to its compact structure and good sealing, the solid insulated switchgear basically does not require maintenance during normal operation, reducing operating costs.

4. The equipment strictly complies with relevant standards and specifications during the design and manufacturing process to ensure safe and reliable operation in various harsh environments.

4. Summary

Solid insulated switchgear is widely used in industrial and civil ring networks and terminal power supply systems, especially in small secondary distribution stations, switchgear, industrial and mining enterprises, airports, railways, commercial areas, high-rise buildings, highways, subways, tunnels and other fields. Its excellent performance and wide range of applications make solid insulated switchgear play an increasingly important role in power systems.

.jpg)